Alternative Fuels & Raw Material (Solid/Semi Solid AFR)

While there is a lot of intense debate going on about the economic growth of India, there is hardly any discussion about the waste resulting from the same economic growth. Rapid urbanisation and industrialisation, increasing household income and changing lifestyles are leading to an increase in the amount of waste generated. As per Central Pollution Control Board (CPCB) data, India generates about 6.2 million tonnes of hazardous wastes annually; with this quantum of hazardous waste generation, local administration, civic bodies and policy makers are seriously concerned, particularly about its effective and safe disposal. Thus, effective waste management is the need of the hour for the country, indeed, imperative for the sustainable growth of the country. One innovative approach to handle the problem of waste management is the Pre- processing & co-processing of waste in cement kilns i.e, use of waste for the partial substitution of fossil fuels in cement kilns.

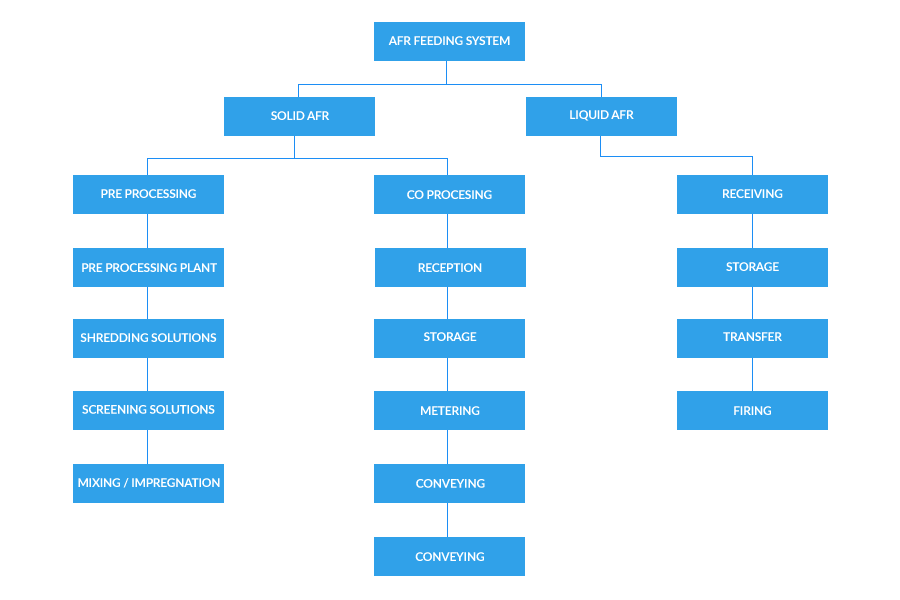

Pre-processing is art of change of waste in to AFR. It not only helps to reduce the size of waste but also helps chemically controlled with proper quality analysis & procedure. Pre-processing includes Shredding, Segregation, Impregnation foreign body removal etc.

Co-processing is the act of adapting an existing industrial process whereby certain so-called ‘waste’ materials may be put to use to serve as alternatives resources as fuels in cement kilns. These materials are generally termed “alternative fuels and raw materials” (AFR).

Over time, Indian cement industry has made significant progress in terms of improvement in energy efficiency and productivity. Still, the use of alternate fuel and raw material (AFR) to replace coal for thermal energy needs, remains an area where the Indian cement industry is yet to catch up with global benchmarks. Though a few cement plants use large quantities and varieties of AFR in their kilns, on an average, co-processing in the Indian cement industry is less than one per cent, compared to European average of 40 per cent.

The use of waste as alternative fuels in the cement Industry has its own benefits which includes:-

- Reduces the use of non-renewable fossil fuels such as coal as well as the environmental impacts associated with coal mining;

- Contributes towards a lowering of emissions such as greenhouse gases by replacing the use of fossil fuels with materials that would otherwise have to be incinerated with corresponding emissions and final residues;

- Maximizes the recovery of energy from the alternative fuel material. All the energy is used directly in the kiln for clinker production.

- Most cement plants noted that use of alternative fuels is important to the continued competitiveness of their plants.

We Sanghavi Engineering has embarked wholeheartedly on a new path of promoting the use of Alternate Fuel and Raw Materials (AFR) through waste management solutions. We are pleased to inform you that, we are in position to offer you complete solution for AFR handling system i.e pre- processing and co-processing of AFR.

Solid/Semi Solid Pre-processing

Pre-processing is art of change of waste in to AFR. It not only helps to reduce the size of waste but also helps chemically controlled with proper quality analysis & procedure.

Pre-processing includes Shredding, Segregation, Impregnation foreign body removal etc

Equipment selection needs to be specific depending on the material’s physical & chemical characteristics.

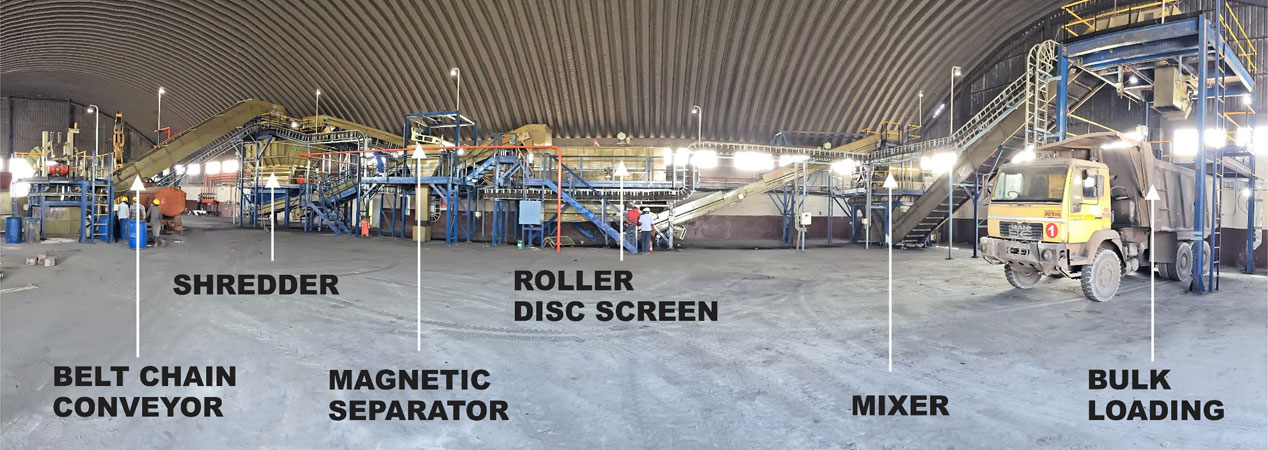

Solid/Semi Solid AFR Pre Processing Solutions by Sanghavi

Depending upon the process requirement and the material characteristics, combination of following equipment can be used to offer a complete solution.

- Primary shredder

- Magnetic Separator

- Star / Disc Screen

- Secondary Shredder

- Air Sifter with cyclone

- Impregnation Mixer

Primary Shredder with Hydraulic Drive

Screening Solutions

Disc Screens are the most efficient screening solution for Two Dimensional and Three Dimensional Materials.

Functional Description:

The mixed material is fed to the screen on the front side by a conveyor belt which is passed over the disc of the screen where it is completely shaken up & down and separated in two fractions.

Required size of material falls down under the screening surface passing through pre-defined gaps ofthe discs.

The over sized material is continued towards the end of the screen for further processing / recirculation.

Features & Benefits:

Shredders for industrial, bulky and mixed waste

Throughput from 1 to 40 tph

Overload Protection

Exchngeable wear parts

Drive arrangement: Hydraulic / Electrical

Materials Handled:

- Bulky waste, industrial waste

- Municipal solid waste

- Metal drums and drums containing liquid, pasty or solid products

- Wooden boards, branches and packages

- Tree stumps and trunks

- Refrigerators

- Lightweight motor cycles

- Carpets and rolls of carpets

- Mattresses (foam and springs)

- Beds (wood, metal)

- Wooden cupboards

- Car seats

- Cardboards, cardboard / paper stacks, phone books, catalogues

- Plastic and rubber (rolls, blocks, production failures)

- Compound and sandwich materials Animal bodies (not frozen)

- Materials coming from river guides

Drive Arrangement

Hydraulic Drive are required for:

- Mixed and unsorted materials

- Material is fed in batches by pay loader / grab etc.

- Materials requiring specific particle size or throughput control and closed loop through screening

- Materials containing non-shreddables

Electric Drive can be used for:

- Sorted and uniform materials

- Material is metered and Conveyor fed

- Materials containing limited non-shreddables

Advantages:

High-torque, low-speed design:

Delivers multipurpose shredding with greater on-line reliability and lower maintenance requirements than other technologies.

Fixing Tools Arrangement:

Unique shrink fix type design for better Shredder performance and increased Tool life.

Shock load absorption:

Geared coupling for electric drives and flow control valves design for hydraulic driven system ensures shock load absorption during operation.

Overload Protection:

Auto reversal arrangement through VFDs in case of overloading.

Out board bearing arrangement:

This arrangement ensures isolation of bearings from the cutting chamber contamination and protects against bearing failure.

Sanghavi offers a full range of energy-efficient electric and hydraulic shredders as well as custom units to meet all processing requirements. We can also offer complete plant along with screening arrangement.