Like a Fluidized Bed Dryer, the Fluidized Bed Cooler also uses the principle of Fluidization for maximum exposure of surface for cooling action. These are simple, compact units designed to cool hot solid materials quickly down to any temperature above ambient.

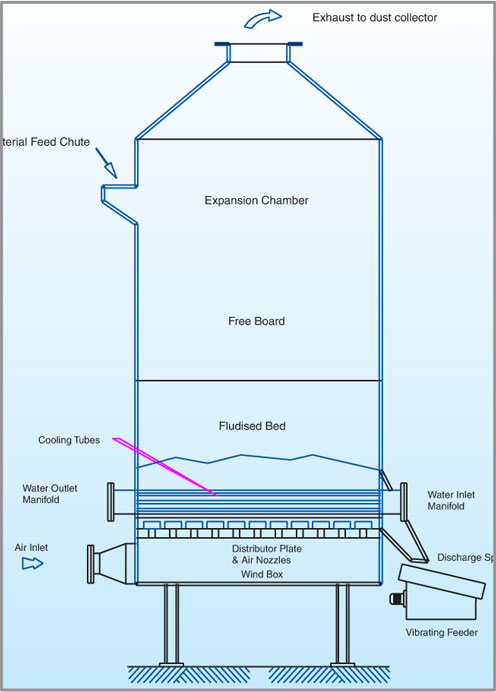

The Fluidized Bed Cooler consists of Two Cylindrical bodies, separated by a Distributor plate. The Distributor plate, which is the top plate of the “Wind Box”, has a number of Air Nozzles through which Cold atmospheric Air is admitted to fluidize the material.

The material to be Cooled, forms a fluidized bed due to the aeration of the same and thus maximum surface comes in contact with the cold air being supplied by the nozzles. The bed contains number of tubes carrying water in it. The spacing of the tubes is such that it provides maximum heat transfer area without interfering with fluidization.

Material to be cooled is fed from one end of the fluid bed and it moves along the bed in a fluid state to the other end of the fluid bed. The Cooled material leaves the Cooler via the discharge chute in to the Vibrating feeder/conveyor. Cold Water flows in the counter current through the tubes that are completely immersed in the material bed.

This is a system where no direct contact of cold water occurs with the material. Most of the heat is removed by the cold water, air only assists in keeping the material in fluid state. The cooling water can be used in another process or recirculated via a cooling tower/ spray pond.

.