Our engineering workshop is well equipped with all the required machineries and facilities required for various machining, repair and retrofitting activities. Some of the specialised activities undertaken by us are:

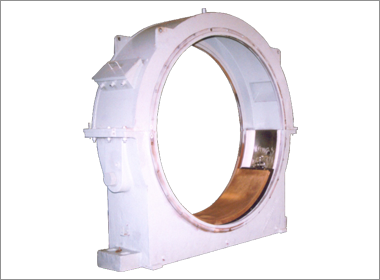

Main Mill Bearing Socket

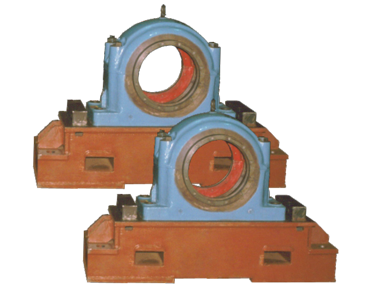

Counter Shaft Bearing Assemblies

We undertake complete design engineering, manufacturing and supply of Counter Shaft Bearing Housing Assemblies for conversion of white metal lined Counter Shaft Bearings into antifriction type Bearing Housings. This has several advantages such as:

- Low maintenance and less down time

- Saving of Electrical Energy

- Employing Spherical Roller Bearings which reduces misalignment between pinion and gear

- Over heating / melting of bearing is eliminated

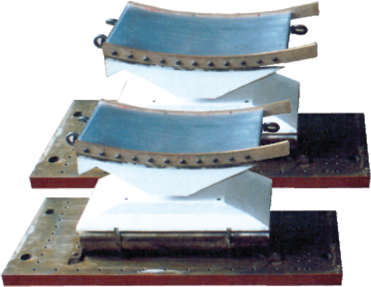

Slide Shoe Assemblies

White Metal Babiting / Lining :

We specialise in white metal lining of main mill bearing sockets / slide shoes with ultrasonically tested bonding quality. Our customers for white metal lining include all major OEM’s in cement industry as well as cement plants for rebabiting as well as new bearings.

Pneumatic Sealing for Rotary Kiln Inlet :

We provide specially designed pneumatic sealing arrangement for rotary kilns of various sizes. This has various advantages over traditional sealing arrangement. Separate literature available on request for Pneumatic Sealing for Rotary Kiln Inlet.

Rotary Kiln Bearing Housing :

We regularly manufacture & supply rotary kiln bearing housing assemblies with spherical machining for various major OEM’s in cement industry.

Stainless Steel Fabrication :

we carry out stainless steel fabrication in various grades of stainless steel such as SS 304, SS 310, SS 316, SS 321. Various types of Stainless steel fabricated items like immersion tubes for pre-heaters, stainless steel dampers etc can be fabricated as per customer’s requirement.