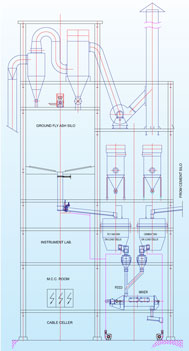

We undertake complete Design, Engineering, Manufacture and Supply of Continuous Blending or Batch Mixing Plants on turnkey basis for various applications like Cement Blending, Dry Mortar Blending, Ferro Alloy Charging, Mixing and Proportioning plants for Iron Ore Pellatizing, Glass batching etc

Mixing Quality

When producing Mixed cements usually two components are mixed in different proportions. A basic component (Ordinary cement, fine cement etc) with a percentage of 50% to 80% and other component (fine fly ash, ground blast furnace slag etc) in ratio on 20% to 50%.

Described here is the mixing process for a two - components mix. In (fig. a) the basic component is displayed as white boxes, the secondary component as grey boxes.

An ideal homogeneous mix (fig. b) where every tiny sampled quantity has exactly the same composition as the entire mix cannot be achieved in reality since the components, made up of irregularly shaped particles with different densities and particle size distribution, are not packed. A uniform random mixture as show in (fig. c) is only theoretically feasible. In practice, the evaluation of a mixture is carried out by taking several samples and by the determination of the proportion of one particular component in every sample.

Two types of Mixers are available:

- Continuous blender / mixer

- Batch blender / mixer

we design manufacture and supply both the types of mixers for continuous operation.