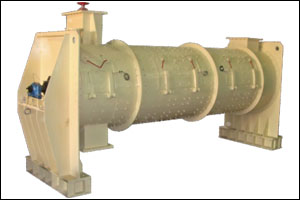

Single Shaft Mixer

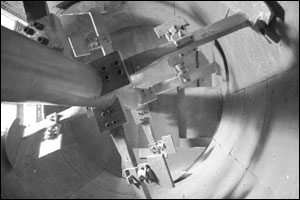

Sanghavi single Shaft mixers operate on the Principle of mechanical fludization of products. In the horizontal mixing system with horizontal drum and horizontally installed shaft, the fluid bed is produced mechanically by the rotation of elements in the shape of plough - shears arranged in a special configuration on the shaft.

The Whirlpool like centrifuged force thus obtained moves the particles through three dimensions for thorough mixing.

In addition the brisk beating action ensures speedy homogenisation and high precision mixing even for ingredients having widely differing particle sizes and bulk density. However individual and complete range of retention time are of great importance. The Mixing is single Shaft blender thus takes place mainly by convection, based on a gentle radial movement; axial movement is limited and accomplished by some shear. The mix passes through the complete length of continuous mixer and is discharged through the manual or automatically regulating adjustable weir. This gives the advantage that the filling reaction and retention time can be easily adjusted.

Mixing Elements for Single Shaft Mixer

Various type of mixing tools are provided for mixing of different products depending upon their material characteristics.

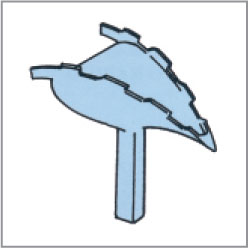

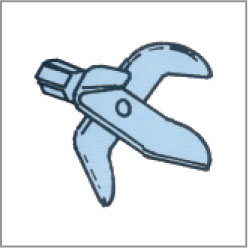

Choppers

Choppers can be used where it is necessary to disperse lumps and balls of product during the mixing process. They are also used during moisturising process for more rapid dispersion of liquid or pasty components , to control agglomeration techniques and in

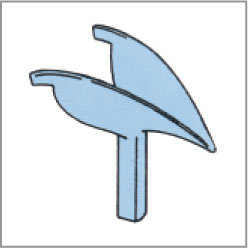

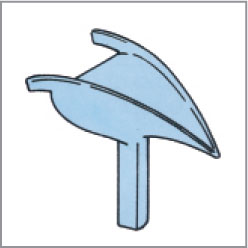

Standard Mixing Tool

Open Mixing Tool

Cup Shaped Chopper

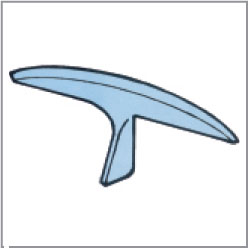

Cut-Edge Mixing Tool

Shovel

Tool

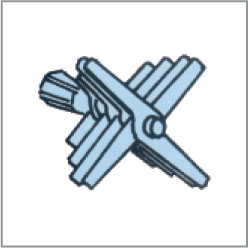

Blade Type Chopper

Selection Chart for Continuous Blender

| Standard Models | Drum Capacity (Litres) | Effective volume at 50% capacity (Litres) | Flow rate at 1 minute Residence time in M3/hr | Drive kW (for Dry Cement Mixer) | Drum Diameter (mm) | Drum Length (mm) |

| SMC 40 | 800 | 400 | 24000 | 3.7 | 720 | 2350 |

| SMC 50 | 1000 | 500 | 30000 | 3.7 | 760 | 2450 |

| SMC 60 | 1200 | 600 | 36000 | 5.5 | 820 | 2750 |

| SMC 70 | 1400 | 700 | 42000 | 5.5 | 870 | 2610 |

| SMC 100 | 2000 | 1000 | 60000 | 7.5 | 920 | 3110 |

| SMC 150 | 3000 | 1500 | 90000 | 11 | 1130 | 3210 |

| SMC 200 | 4000 | 2000 | 120000 | 15 | 1220 | 3650 |

| SMC 250 | 5000 | 2500 | 150000 | 18.5 | 1290 | 4110 |

| SMC 300 | 6000 | 3000 | 180000 | 22 | 1370 | 4260 |

| SMC 350 | 7000 | 3500 | 210000 | 22 | 4450 | |

| SMC 400 | 8000 | 4000 | 240000 | 30 | 1520 | 4560 |

| SMC 500 | 10000 | 4500 | 270000 | 45 | 1620 | 4680 |

| SMC 600 | 13000 | 6500 | 390000 | 75 | 1770 | 4310 |

| SMC 700 | 14000 | 7000 | 420000 | 110 | 2130 | 5910 |