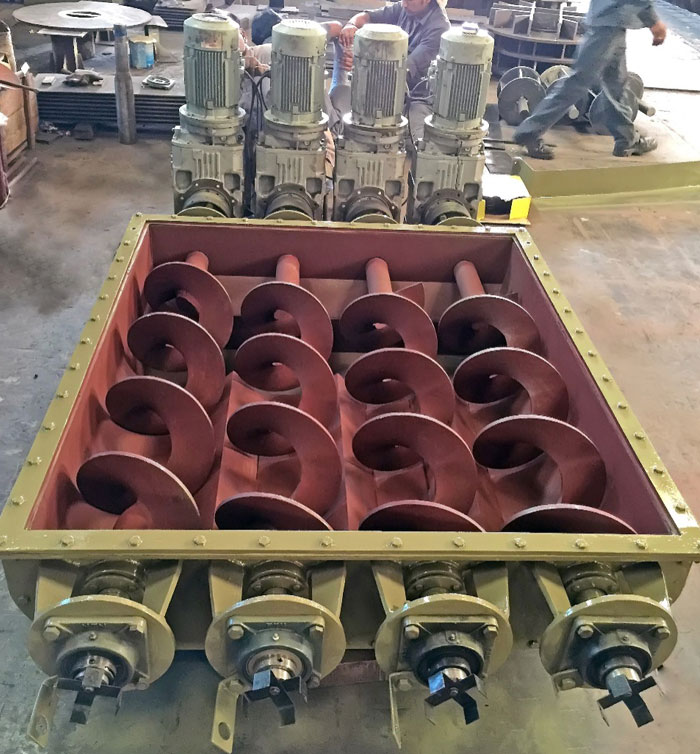

Mixer

Twin Shaft Mixer for Impregnation / Blending of Various fuels.

Batch Operation.

Pneumatically Operated Bottom Discharge arrangement.

Hydraulic/ Electric Driven.

AFR Co-processing System

Co-processing is the act of adapting an existing industrial process whereby certain so-called ‘waste’ materials may be put to use to serve as alternatives resources as fuels in cement kilns. These materials are generally termed “alternative fuels and raw materials” (AFR).

Depending upon the process requirement and the material characteristics, following equipment can be used in respective sections to offer a suitable solution.

Reception

- Live Bottom Screw Docking Station

- Truck Unloading Station

Storage with controlled discharge

- Push / Live Bottom Floor – Hydraulically operated

Conveying

- Mechanical

- Chain Belt Conveyor

- Side Wall Cleated Conveyor

- Skip Hoist

- Belt Conveyor

- Pneumatic

- Blow through Rotary Feeder (for pneumatic conveying)

Feeding

- Flap Damper

- Rotary Air Lock

- Pneumatic Shut-off Gate

Live Bottom Screw for Agro Waste

Shaft less Screw Extractor for Pharma Waste

Push Floor Extractor