Side Wall Conveyor

Chain Belt Conveyor

Blow Through RAL

Few Points to Ponder for AFR

AFR is different.

AFR has mostly non standard material properties. Specially designed equipment need to handle it.

Flexibility is the key

Changing waste markets and AFR properties call for handling installations with high versatility

Be Safe - Fire is the Greatest Enemy of AFR

Fire detection & protection system as well as water sprinkler system at correct locations should be installed as precautionary measures for safe handling.

Fuels Not Suitable for Cement Kiln

- Electronic Wastes

- Whole Batteries

- Bio Active Medical Waste

- Mineral acids and corrosives

- Explosives

- Asbestos

- Radioactive Waste

- Unsorted Garbage

Liquid AFR System

Liquid Alternate Fuels

- Spent Solvents

- Pharmaceutical

- Agro Chemical

- Waste Oils

- Emulsions

- Waste Water

- Depleted Pesticides

Liquid AFR System Advantages

Liquid fuels can be atomized with compressed Air with solid particle of size less than 1- 8mm.

Existing firing system can be used with less modifications.

Does not require heavy structural engineering.

Less Power consumption

Liquid AFR Handling System

- Receiving Station

- Storage Station

- Transfer Station

- Firing Station

System Description

Receiving and Storage Station:

- Receiving Liquid solvents are carried to site in Tankers or barrels and are transferred into the properly designed storage tanks.

- Nitrogen blanketing is to be present in the tank to avoid any vapors coming out of the storage tank to atmosphere.

- Liquid solvents are unloaded by using pumps, filtered and are transferred to storage tanks.

- Storage tanks are coated inside with Special lining to avoid corrosion and required safety equipments are provided.

- Agitator is provided in the tank for maintaining the homogeneity of the liquid.

- Grounding system is provided to neutralize the static charges developed during the transfer of liquid

Transfer and Firing Station:

- Liquid stored in the tank is filtered and thus transferred for firing.

- Seal-less Pumps are used for the transfer of liquid from the storage tank.

- Lined Pipes, bends and fittings are used for conveying of the liquid.

- Control Valves, Transmitters and Switches are provided for easy monitoring and control of the system.

- Drain out Pump is provided for removing the liquid from the line during emergency.

- Drain out valves are provided in the line

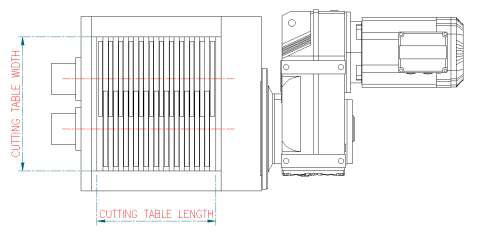

Twin Shaft Shredder

Features:

- Heavy duty, welded and stress free annealed construction

- Hexagonal shafts

- Interchangeable cutting tools

- Automatic reversing controller with overload detection

- Cutting width: 10 - 31 mm

Applications:

- Biomass and food waste recycling

- Recycling of plastics and foils

- Recycling of production waste

- Destruction of data carriers

- Processing raw materials

- Shredding of residual and hospital waste, etc.

Optionals:

- Stainless steel liner for cutting chamber

- Special sealings for shredding with high liquid content

- Bottom screens: 10 - 60 mm

| Model | TS3E - 7.5 | TS3E - 15 |

| Cutting Table width | 500 | 500 |

| Cutting Table Length | 445 | 610 |

| Drive Power(kW) | 7.5 | 15 |

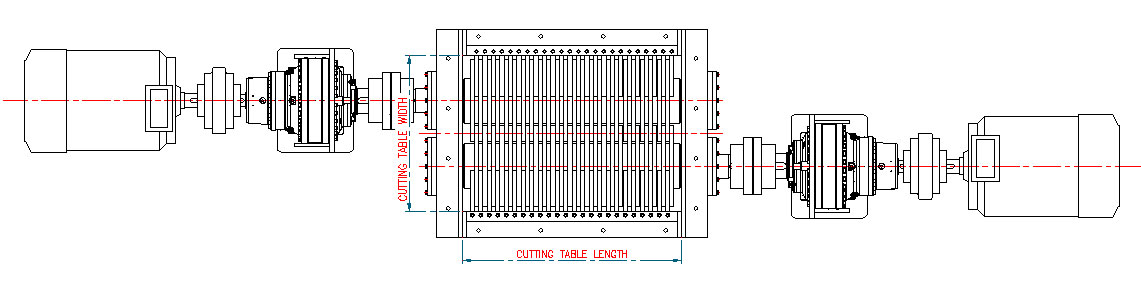

Twin-shaft Shredder (Dual Drive)

| Model | TS2DE-37x2 | TS2DE-55x2 | TS2DE-75x2 |

| Cutting Table Width | 750 | 750 | 750 |

| Cutting Table length | 750 | 1050 | 1450 |

| Drive Power (kW) | 2x37 | 2x55 | 2x75 |