We also have a special design for Fluidized Bed Hot air Generator, which is more suitable for using Coal of high ash content.

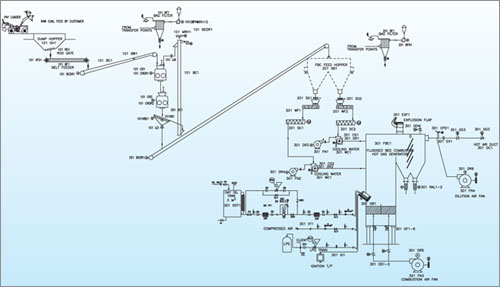

Crushed Coal of approx. 3 mm to 6 mm are fed to the Fluidized Bed Hot Air Generator through a suitable conveyor. Initially the bed is heated up using a pressure atomized fuel oil burner. Once the bed Temp is raised to sufficient heat, Charcoal is fed in to the bed to raise the bed Temp further to ignition temp of Coal. Now the Coal is fed in to the chamber and coal starts burning and volatiles burn in the free board and the Hot Gas of about 900 to 1000 deg C is produced.

Bed Temp is controlled by varying the feed rate of coal. A high Temperature switch with an alarm automatically cuts off coal feed, if the bed Temp goes too high.

The hot Gases are first made to pass through 2 to 3 sharp changes of direction to trap the fly ash in the Gases.

The bottom lump ash is removed through an ash drain in the bottom of the sand bed. This drain discharges the ash through a pipe to the ash handling system

Advantages :

- The Fluidized Bed Hot Air Generator is very efficient.

- Ensures very uniform temperature conditions

- High degree of heat and mass transfer.

- No need for elaborate Sealing Arrangement.

- Better Control of Hot gas generation due to the controlled feed.

- Complete combustion and higher efficiency.

- Elimination of Coal grinding mill from the Circuit.

- Elimination of Grit separator.

- Elimination of costly Bag Filter

- Saving on Power due to no heavy-duty motors (coal mill)

- Elimination of screw pump with roots blower for fine coal transportation

- Less maintenance due to fewer moving parts

- Compact Layout

- Lesser number of Equipments

- Reduce inventory in maintenance spares.

- Fluidized Bed Hot Air Generator are completely automatic