Principal application is to increase output (tons/hour) at constant cement fineness (cm2/g)

Introduced at low dosage, usually

- between 0.01 and 0.10% (most preferably at 0.01 – 0. 1%)

Influence on cement quality is usually small (or) not the main aim of its application.

These products are based on glycol and amine chemistry.

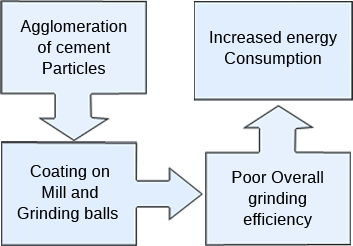

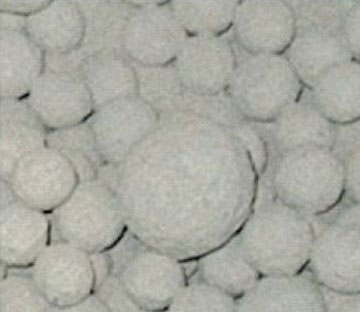

- Agglomeration

- Cement Grinding Aid Mechanism

- Effects of Cement Grinding Aid

- Cement Grinding Aid Mechanism in VRM

- Benefits of Cement Grinding Aid

- CGA reduces the inter-particle attractive forces of cement which causes agglomeration of cement grains.

- CGA are adsorbed on the newly created surface, neutralising electrical charges and thus reducing their tendency to re-agglomerate. Hence, the cement grains show a lower resistance to comminution.

These provides benefits to grinding efficiency by

- Reduction in agglomeration and coating of the mill internals.

- Improved dispersion of feed to the separator - Increased separator efficiency and lower by-pass.

- Reduction in the mill filling level.

- This theory is proved by the fact that all the chemicals which are affecting the grinding process have strong polar characteristics.

- CGA acts on stabilizing the grinding bed in the Vertical Roller Mills.

- At same time, CGA prevents air entrainment in the bed, thus reducing drastically mill vibrations.

- Furthermore, due to the addition of CGA, the amount of water required to achieve this effect is much lower – Results in improved strengths performance & requires lesser heat demand for drying.

(increased amount of water in the bed results in lower strengths and higher heat demand essential for drying the ground cement).

- Improvement in Grinding Efficiency.

- Better Particle Size Distribution - Narrower PSD.

- Increment in Mill Output.

- Reduction in Specific Power (kWh/ton) of Grinding.

- Reduction in Mill Run Hours.

- Improvement in Cement Handling Characteristics.

- Increment in Cement Flowability & Reduction in Pack-Set.