Aero-slides

These are most commonly known as pneumatic gravity conveyors and used for transporting/feeding fine & pulverized material. It consist of two compartments separated by porous fabric. Bottom compartment is supplied with air and upper compartment carries material. The inclination and air pressure moves the material in forward direction. The inclination is usually between 8 to 10 degrees to the horizontal. We have standardized design for aero-slide ranging from 150 mm to 865 mm wide for various length for maximum conveying capacity upto 1400 Cu. Meter/hour.

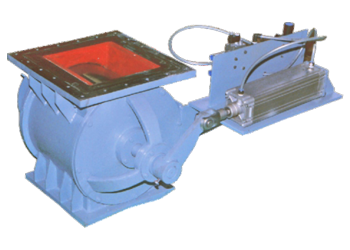

Flow Control Gate

This equipment is motorised actuator operated and used for infinite quantity controlling the rate of material flow in the range of 0-100%.

We manufacture flow control gate ranging from 200 material. mm to 850 mm size depending upon the volumetric capacities. The housing and rotor can be offered for both options, casting & fabricated design. Special FELT material is used for sealing to ensure dust tight operation.

Dial type continuous mechanical indicator is provided as standard feature of the equipment. Optionally potentiometer with transmitter can be provided for remote indication of gate position.

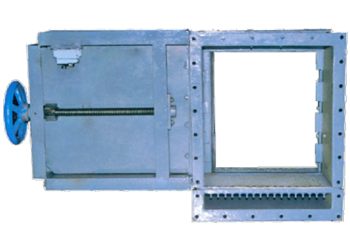

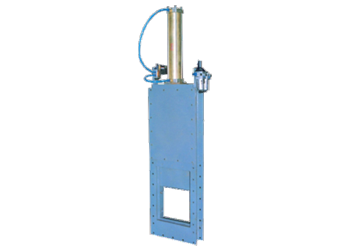

Rotary Shut Off Gates

This equipment is used for ON/OFF purpose of material flow. Construction features are same as flow control gate but on / off operation is through pneumatic cylinder.

Design is available from 200 mm to 850 mm size depending upon volumetric capacities. Due to rotary type of construction sealing efficiency is much better than slide type shut off gate.

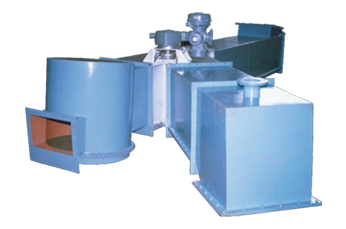

Splitters

A Splitter is used for dividing the flow of material between 20 - 80% of the maximum flow rate. Motorized Splitters are installed as a part of aero slide system. This is a specially designed equipment to split the Raw meal in desired proportioning quantity for feeding into two different pre-heater streams. The operational control of the actuator is done from control room by sensing the pre-heater string temperature and thereby proportionately adjusting the splitter gate position.

Side Discharger

This equipment is used for discharging material at one side of the conveyor anywhere in line of the conveying system.

Bottom Discharger

This equipment is used when material is to be conveyed straight or to be discharged underneath the conveying system. It consists of a movable aerated bottom, which is used for discharging material.

Divertors

These are generally used under silos/or at the discharge of any conveyor equipment.

These can be supplied either pneumatic / motor operated with branching chutes of 30 to 45 degrees inclinations. This can be supplied in fabricated MS/SS construction with or without wear liners.

Nib Trap

Nib Trap arrangement consists of Aerated Conical Chamber design gate with deep material chamber. This is installed in between the aero slides. Separate high pressure Roots Blower is used for aeration of Nib Trap. Fine material (Cement/Ground Slag) will be conveyed through aero slides & the Nibs shall get collected in the Nib trap. Two Nos. manual Slide Gates are provided below the Nib trap for removal of Nibs as & when required.