Currently most of cement plants are opting for manufacturing of Pozzolona Portland cement using Dry Fly Ash. The dry fly ash is collected directly from the Thermal power plants and transported to plant by road tranport using bulker/ trucks or by dense phase conveying system ( if thermal power plant is in proximity of cement plant).

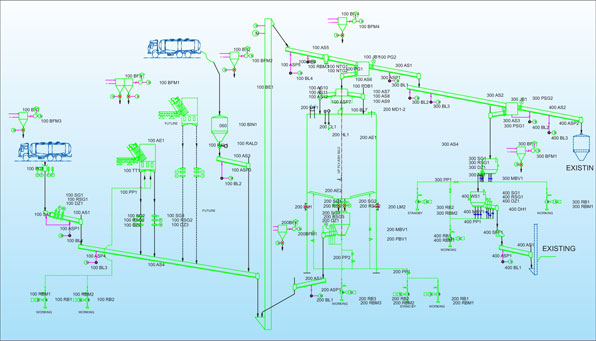

We offer complete solution for fly ash handling system. The system can be divided in two parts

- Dry flyash collection and loading system

- Unloading of dry flyash and feeding system to cement mills.

In collection system, the material is collected from ESP through pneumatic system and transferred to intermediate storage silo in thermal power plant. The storage silo is provided with suitable aeration & extraction system for loading the material in to Bulker or Railway Wagons. We also undertake conversion of Railway Wagons in to suitable aerated wagon for transporting the material.

The Material transported to plant has to be unloaded quickly and transferred to storage silo. We have developed various unloading mechanism for different type of vehicles. The pneumatic coupler arrangement developed by us for bottom discharge bulkers have been highly appreciated through out country due to quick and economic unloading system. This has unique advantage that bulker can be unloaded in 5-6 minutes and material is transferred to silo with help of Belt bucket elevator without using heavy power consuming compressor used in conventional way of unloading of bulker. We also aerated pit design for unloading open trucks and railway wagons.

The unloaded material is stored in storage silo, which can be of inverted cone or flat bottom design. The suitable aeration is provided based on the extraction rate requirement. Depending upon plant design layout, if the cement mill is located near by silo then the continous weighing arrangement is provided below silo or material is conveyed up to day bin by air slide or pneumatic conveying system in case silo location is far away from cement mill section. In case of day bin, aeration arrangement is provided for smooth extraction of material and fed to Solid flow meter for feeding metered quantity of material to cement mill. We have executed complete system for various customer like M/s Ultratech Cement (various plants), M/s ACC Ltd. M/s Ambuja Cements, M/s Binani Cement Ltd, M/s Heidelberg Cement, M/s Jai Prakash Associates and many others.